Recyclables—where do they go and how do they get there?

By: Larry Newman

Recycling is a big business. Although the City collects the material in blue, black, and green bins, others do the separation and processing into marketable products. Processing equipment, especially for plastics and metals, is now quite mechanized or automated with humans basically doing quality control and management.

For Ottawa, Cascades Recovery at 2811 Sheffield Rd. is where the processing takes place. The City collects and transports the material to Cascades and Cascades separates the various kinds of material and bundles/bales it for shipping. Once a month, the City accepts bids for each of the fourteen different post-consumer products that Cascades extracts from our recycled material. The highest bidder arranges transport and takes it away for use in making other products.

This is the first of two articles that will trace the route taken by our recyclables from curbside to new product. This article will concentrate on Black Box material.

The City of Ottawa lists 13 different kinds of materials that can be put in a black box for recycling. All of those materials are called either paper or paperboard by the Paper Products Industry. These recycled paper products are separated by Cascades Recovery into three different materials that might be called feedstocks as they are used, usually in combination with virgin fibre, to make other paper-based products. They are newspapers, corrugated cardboard, and boxboard.

Everyone knows what newspapers and corrugated cardboard are. Boxboard is the packaging material commonly used in cereal and shoe boxes and other similar packaging. Although Cascades doesn’t produce mixed paper, which is a mix of boxboard and corrugated cardboard and some newspaper, other plants in Ontario separate poorer or dirtier examples of cardboard, corrugated, and newspaper into this category.

After collection and delivery to Cascades’s sorting plant, the process begins by dumping all of the material onto a conveyor belt. As this material goes through the machinery, different-sized disc screens separate rigid cardboard from pliable paper, with workers performing the sort of smaller boxboard from paper, and removing whatever waste is found. This separation process ends when the final three products find their way to separate baling areas. These bales are then sold to the highest bidder. For all of the products from both Black and Blue Boxes, Ottawa has as many as 27 bidders each month.

The highest bidder takes delivery of the separated product and begins the process of breaking it down into constituent parts by a paper or pulp mill. The first step for all grades is to break it down into a kind of watery slush. This can be washed and treated to remove staples and other contaminants. For the poorer grades, most of the treatment ends here and products such as home insulation and hydroseed result. One step up in grade is basically pulped mixed paper that is molded into shapes like coffee cup trays, egg cartons, and forms to protect products from damage during shipping.

For boxboard material, further processing removes glue, de-inks, removes small particles, then adds bleach to obtain a consistent light colour. The product with a grey colour is used for cardboard containers not requiring high brightness. The higher-grade material can be treated with clay or other materials to form a surface that will take printing to make a high-value packaging product. The photo above shows an egg carton with a low-grade molded product to cradle the eggs glued to a boxboard cover to make it pretty.

For boxboard material, further processing removes glue, de-inks, removes small particles, then adds bleach to obtain a consistent light colour. The product with a grey colour is used for cardboard containers not requiring high brightness. The higher-grade material can be treated with clay or other materials to form a surface that will take printing to make a high-value packaging product. The photo above shows an egg carton with a low-grade molded product to cradle the eggs glued to a boxboard cover to make it pretty.

The corrugated cardboard is processed to make two types of cardboard called medium (the inner layer) and linerboard (the smooth outer layer of corrugated cardboard and paper bags). Finally, the best grade of newspaper goes to a paper mill to be bleached and join the stream of virgin fibre (from spruce and balsam fir) to be pulped together. The pulp is poured onto a screen, drained, flattened, and dried to return anew to your morning newspaper.

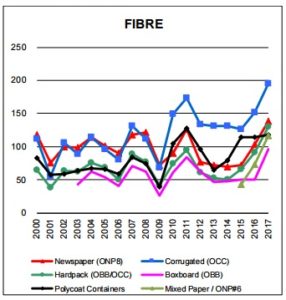

I began by saying that this is a big business. Ottawa collects 52,000 metric tons of paper and paperboard material per year. Buyers vie to feed their mills with this material after separation. The accompanying chart published by Reclay StewardEdge for the Province of Ontario shows how much the price has increased in the last six years.

Ottawa’s revenue from all recycled products (not just paper and paperboard) was $9.5 million last year. This offsets over half of the costs of recovery ($18 million). The Province kicks in about $5 million and the City picks up the rest. In spite of this high-value product, we still only recycle about 2/3 of the paper and paperboard that we use. Although that is twice as good as recovery was in 1990, we still have a way to go.